Foundry & industrial processing Machinery EQUIPMENT & SYSTEMS

U.S. & Canada Call 1.800.457.5456

Articles

Home Articles

MOLDMAKING & COREMAKING AUTOMATION TECHNOLOGIES REDUCE VARIABILITY TO INCREASE QUALITY

- Jim Gauldin

English PDFSpanish PDF

CASE STUDY: HIGH-DENSITY PNEUMATIC SYSTEM IMPROVES COMPLEX CORE ROOM EXPANSION

- Jim Gauldin

English PDFSpanish PDF

Improve Production By Upgrading Existing Equipment

- Jack Palmer

Whether you are a jobbing foundry or a global mega-foundry, turning to your suppliers to ask how to quickly increase production using your current equipment, is a

common request.

Full Article

English PDF

Spanish PDF

Review, Restate & Verify

- Jack Palmer

As a custom, machinery, design and build company, communication is absolutely critical and the difference between delivering custom equipment on-time, or reworking it on the shop floor and delivering late.

Full Article

English PDF

Spanish PDF

How to Properly Clean & Maintain Mixing Chambers

- Jack Palmer

There is tremendous amount of excitement when a new mixer is installed. Operators are formally trained on its operation, cleaning, and maintenance.

Full Article

English PDF

Spanish PDF

RFID Basics for Core & Mold Making

- Jack Palmer

Many human errors in supply chain, inventory management, and production can be easily solved with RFID (radio frequency identification tags). RFID can accurately count and track your incoming boxes, raw materials, inventory, tools, and equipment as well as ensure your production machine settings are correct.

Full Article

English PDF

Spanish PDF

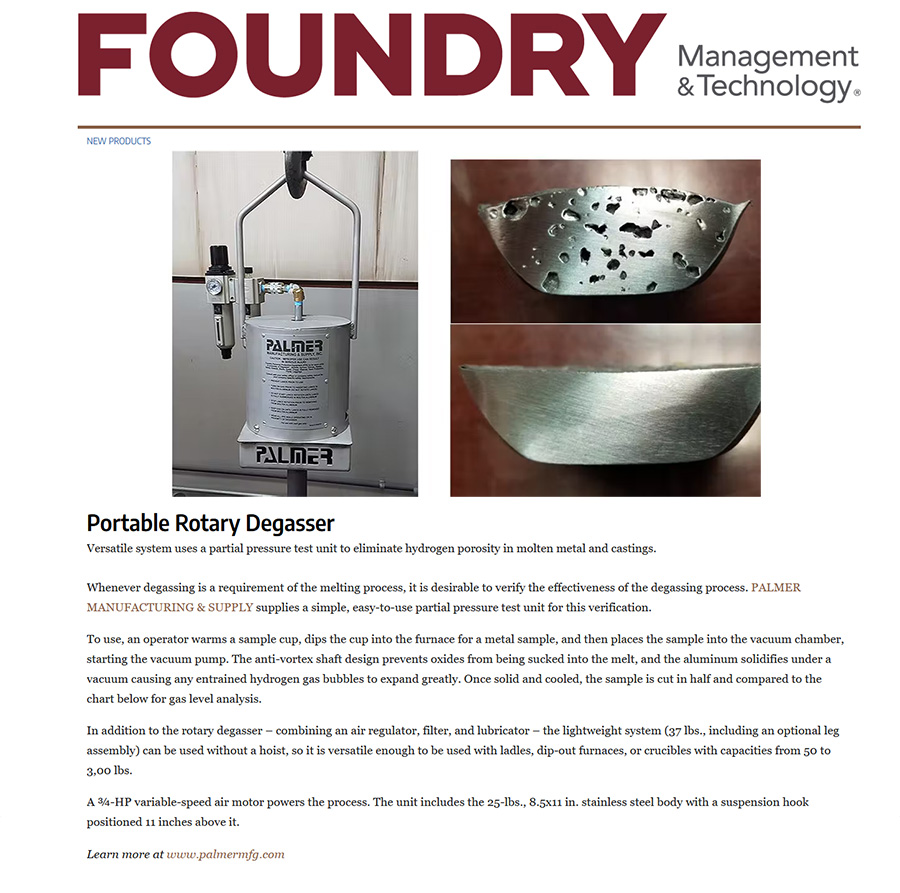

Portable Rotary Degasser

Portable Rotary Degasser

Full Article

English PDF

Evolving the Foundry Cleaning Room with Automatic Grinding

- Palmer Manufacturing

Evolving the Foundry Cleaning Room with Automatic Grinding

Full Article

English PDF

Spanish PDF

What You Need To Know About Foundry Engineering

- Jake McGowan

What You Need To Know About Foundry Engineering

Full Article

English PDF

Spanish PDF

New No-Bake Line Cuts Handling

- Jack Palmer

New No-Bake Line Cuts Handling

Full Article

English PDF

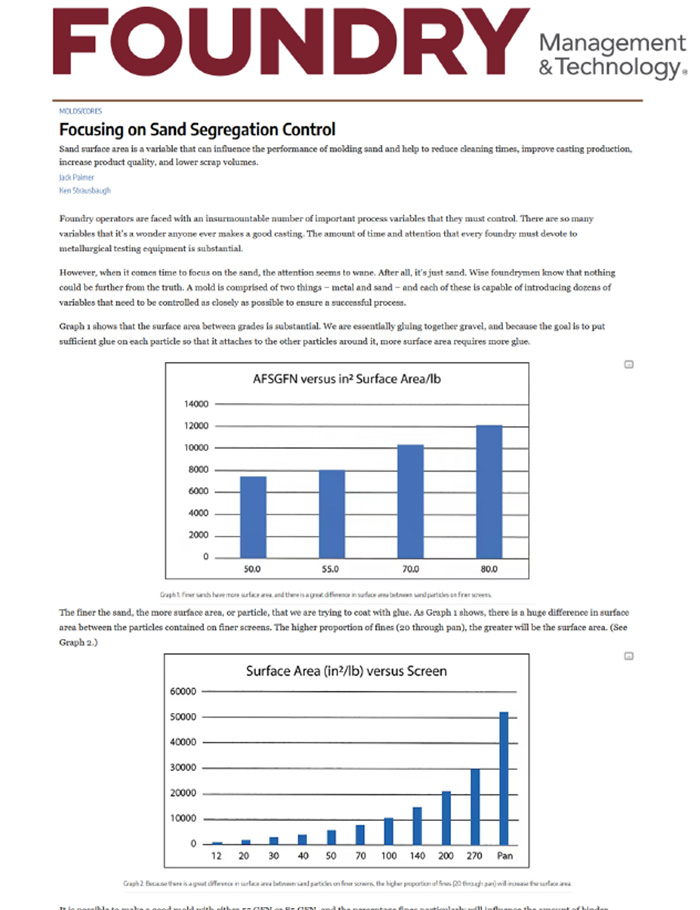

Focusing on Sand Segregation Control

- Jack Palmer

Focusing on Sand Segregation Control

Full Article

English PDF

Fear and Loathing in Las Manufacturing

- Jack Palmer

Fear and Loathing in Las Manufacturing:

Full Article

English PDF

Spanish PDF

Advances in Sand Reclamation

- Jack Palmer

Now is the time to be look at newer sand reclamation technologies, to reduce cost and environmental impacts, and to enhance casting quality.

Moldmaking & Coremaking Automation Technologies Reduce Variability to Increase Quality

- Jack Palmer

Moldmaking & Coremakinjg Automation Technologies Reduce Variability to Increase Quality:

Full Article

English PDF

Spanish PDF

Lowering Labor Costs for No-Bake Molding

- Jack Palmer

Sand molding systems can be enhanced with automation and other technologies, to perform reliably without an operator.

Selecting & Installing The Right Sand Heater

- Jack Palmer

Selecting & Installing The Right Sand Heater:

Full Article

English PDF

Spanish PDF

Understanding Mixer Pumping Systems

- Palmer staff

Understanding Mixer Pumping Systems:

Full Article

Maintenance & Troubleshooting of Pneumatic Conveying Systems for Sand in a Foundry

- CHRIS DOERSCHLAG

English PDFSelecting the Right Sand Heater

- Jack Palmer

For foundries that prepare chemically bonded sand for molds and cores, optimizing the process means understanding and evaluating the primary features and options for water-based and electric-resistance systems.

Importance of Compaction

- Jack Palmer

Importance of Compaction:

Full Article

English PDF

Spanish PDF

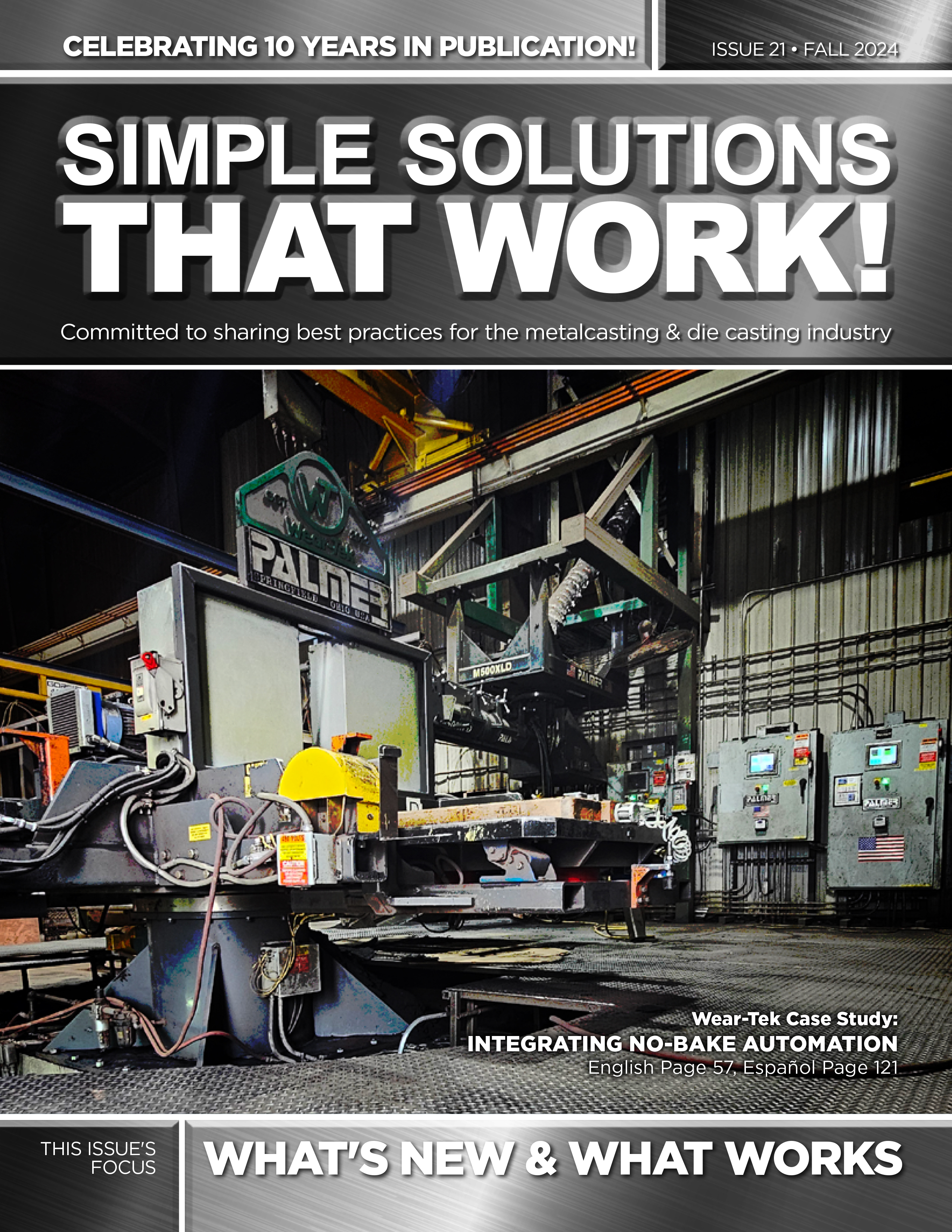

Bold Installation of No-Bake Automation

- Jack Palmer

Bold Installation of No-Bake Automation:

Full Article

English PDF

Spanish PDF

Guidelines for the Successful Installation and Operation of a Pneumatic Sand Conveying System

- CHRIS DOERSCHLAG

English PDFKeeping Jobbing Foundry Coremaking Fast and Flexible

- Jack Palmer

The main advantage of a jobbing shop must be its flexibility and “first time right” capability. All components and processes have to be correct and of high quality the first time.

Molding Basics Mixer and Compaction Calibration

- Palmer staff

Molding Basics

Mixer and Compaction Calibration:

Full Article

How to Upgrade Equipment & Systems Controls

- Palmer staff

How to Upgrade Equipment & Systems Controls:

Full Article

Adjusting Sand Classifiers to Reduce Fines

- Ken Strausbaugh

There are ways to elevate the volume of fines removed, but watch the exhaust velocity or risk losing an excessive amount of larger sand particles.

Greener, Cleaner, Leaner, More Productive Machines

- Ken Strausbaugh

Greener, Cleaner, Leaner, More Productive Machines:

Full Article

English PDF

Spanish PDF

Green Sand to No-Bake Conversion at American Foundry Group

- Jack Palmer

Green Sand to No-Bake Conversion at American Foundry Group:

Full Article

English PDF

Spanish PDF

Design Trends for Automated No-Bake Molding Systems

- Jack Palmer

Available technologies make productive, affordable, profitable systems possible for any foundry. Article in the January 2016 issue of Foundry Management & Technology Magazine.

Prevention of Defects with Venting

- Jack Palmer

Prevention of Defects with Venting:

Full Article

English PDF

Spanish PDF

Damn Sand Gets In Everything

- Jack Palmer

Damn Sand Gets In Everything:

Full Article

English PDF

Spanish PDF

Maintenance & Troubleshooting of Pneumatic Conveying Systems for Sand in a Foundry

- CHRIS DOERSCHLAG

English PDFCosts and Consequences in Buying Used Equipment

- Jack Palmer

There are times when used equipment is a good financial strategy, and there are other times when it makes no sense. Article in the January 2015 issue of Foundry Management & Technology Magazine.

Basic Principles of Sand Mixing

- Jack Palmer

Even with advanced timers, flowmeters, and valving, the objective is to make the initial sand usable, and exactly the same as the sand before it. Article in the January 2014 issue of Foundry Management & Technology Magazine.

The 5 C’s of No-Bake Molding

- Jack Palmer

Properly managing coating, “cooking”, coring, closing, and clamping will result in a safe and productive production line. Article in the January 2013 issue of Foundry Management & Technology Magazine.

Olson Aluminum Castings Foundry Expansion

Featured in Modern Casting, Palmer Manufacturing & Supply Co., foundry expansion at Olson Aluminum Castings in Rockford, IL.

Considerations for Reclaiming Chemically Bonded Sand

- Jack Palmer

To learn more about sand reclamation, read Jack Palmer's article on Consideration for Reclaiming Chemically Bonded Sand. Article in the January 2012 issue of Foundry Management & Technology Magazine.

Thermal Sand Reclamation

Palmer Manufacturing & Supply Co., thermal sand reclamation technology featured in October 2011 edition of Modern Casting.

RFID for Foundry Mold and Coremaking

In this article featured in the October/November 2010 edition of Cast Metal & Diecasting Times, Jack Palmer, President of Palmer Manufacturing and Supply, Inc., discusses the benefits of using radio frequency identification tags in foundry production.

Choosing No-Bake Molding Systems for Jobbing Foundries

- Jack Palmer

The success of any molding system depends on the answers to a series of basic questions.

Foundry Improves Core Operations

With Palmer RFID Coremaker, foundry improves core operations.

Dualtech Does Damage Control

After a devastating fire, Dualtech made castings again within seven weeks and avoided losing customers accustomed to four-week lead times, thanks in part to Palmer Manufacturing's quick response.

Core Blower saves small foundry $30,000/Yr, eliminates coreroom personnel.Core Blower saves small foundry $30,000/Yr, eliminates coreroom personnel.

Copyright © 2025 Palmer Manufacturing & Supply, Inc. | Terms and Conditions | Privacy Policy