Foundry & industrial processing Machinery EQUIPMENT & SYSTEMS

U.S. & Canada Call 1.800.457.5456

Palmer Technical Sand

High Performance Spherical Ceramic Sand

For Metalcasting Mold & Core Production

All foundries are facing increasing regulatory pressure to eliminate silica sand. Palmer Technical Sand provides a solution to this problem while increasing casting quality and reducing scrap.

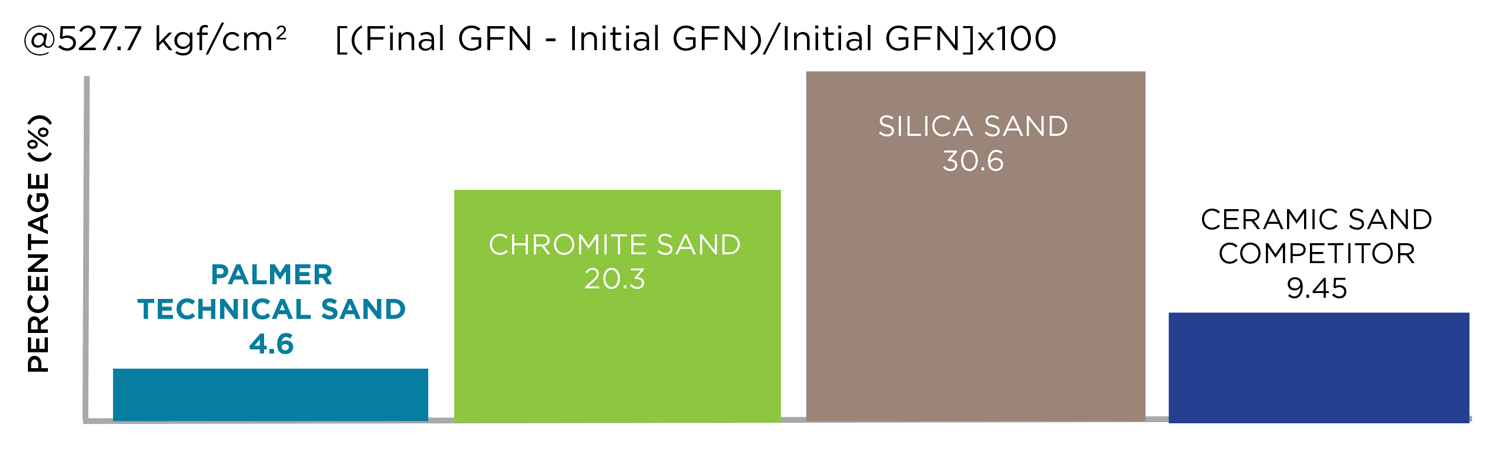

Unique properties allow for exceptional benefits in the cores and mold process for metal casting. Sand grain crush resistance is superior compared to silica, chromite, and most ceramic sands, allowing for it to be more efficiently reclaimed in mechanical or thermal applications.

MOLD & CORE APPLICATIONS USING PALMER TECHNICAL SAND

- Aluminum automotive engine parts

- Stainless steel marine components

- Cast iron valves

- Alloys for heavy engine parts

- Carbon steel turbines

- Non-ferrous alloys aircraft parts

- Special non ferrous alloys for complex & thin wall components

Features & Benefits

- Provides superior finish in 3D sand printing applications

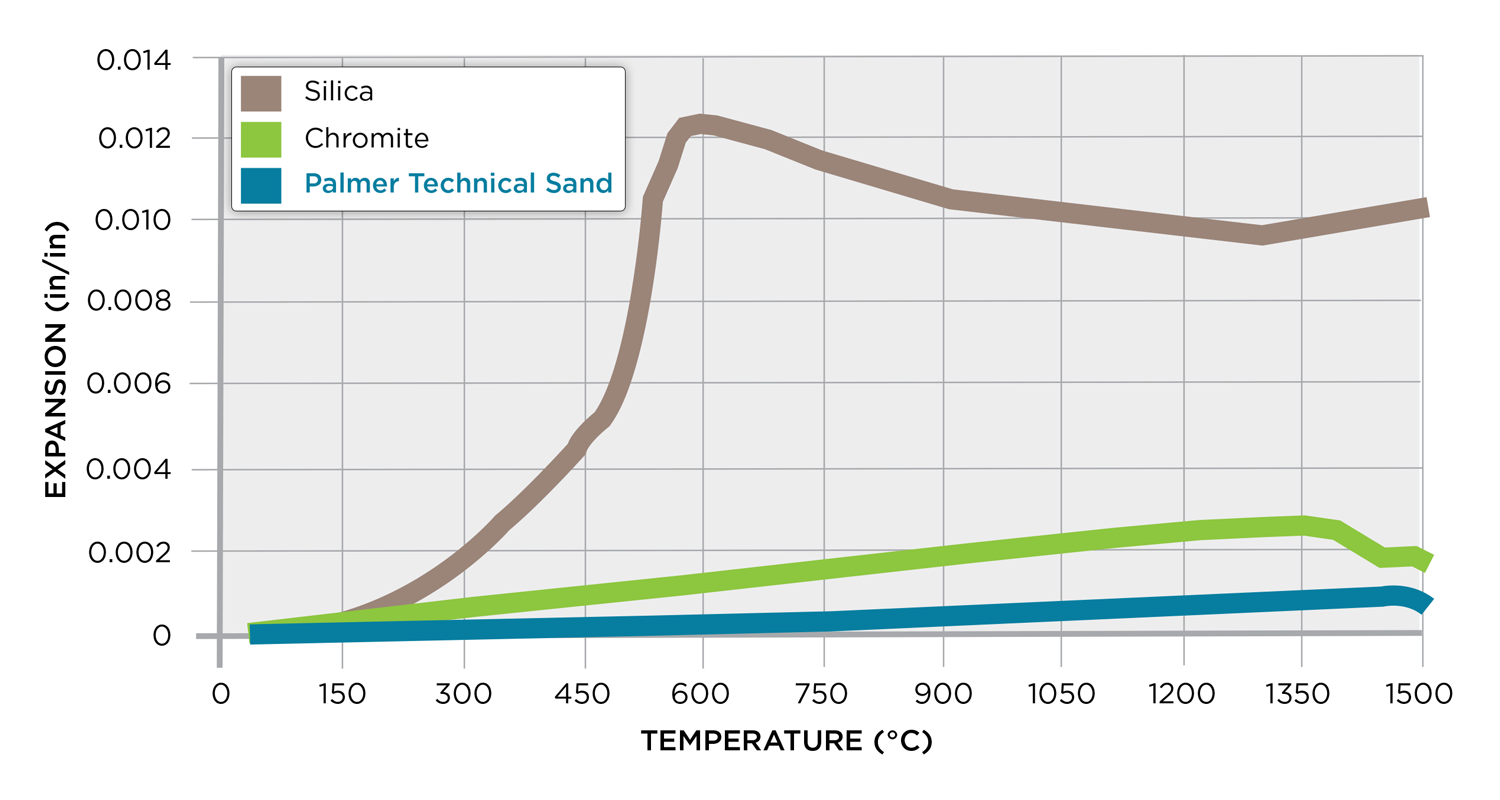

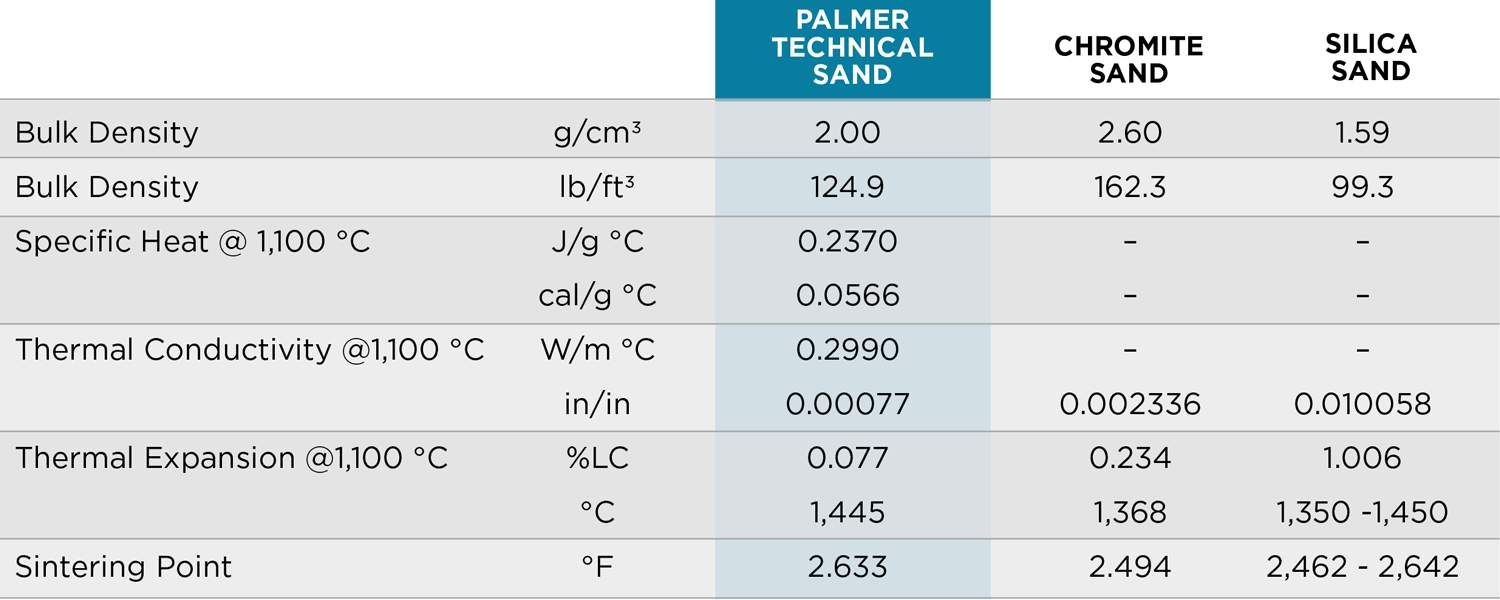

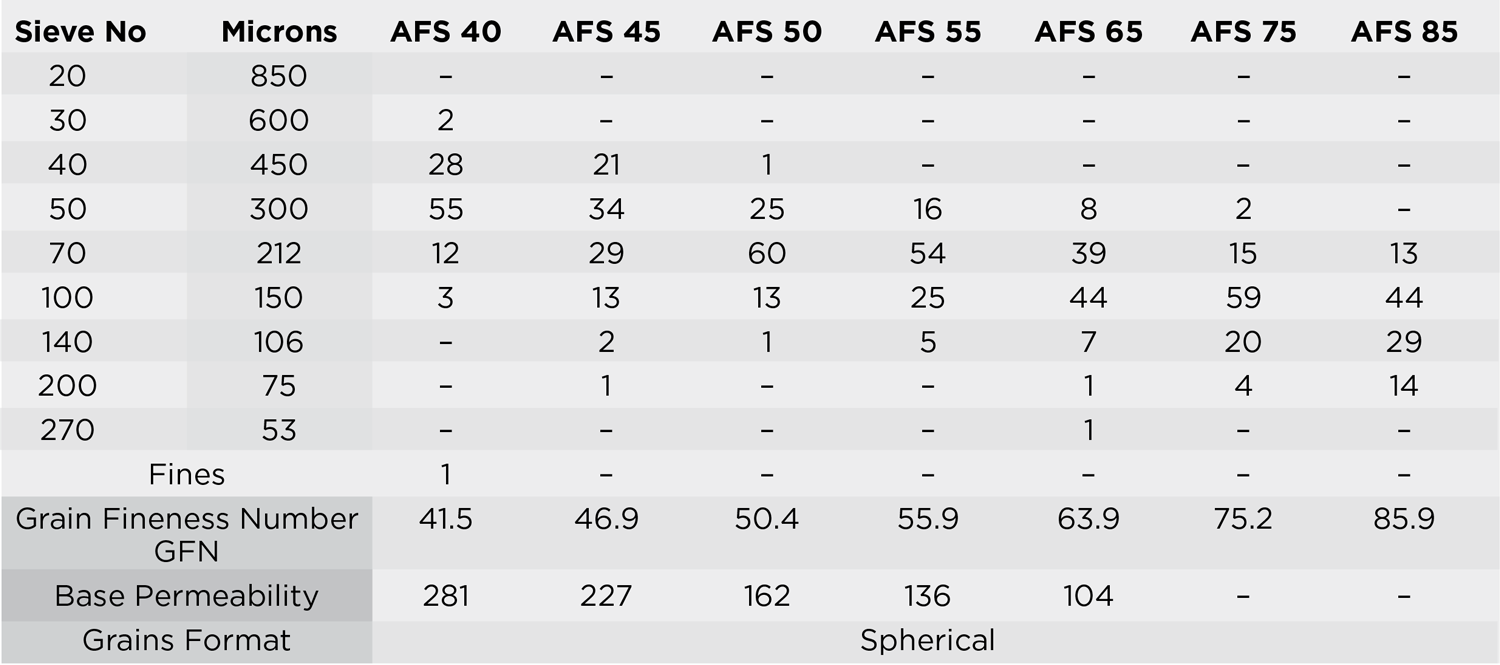

- Low thermal expansion eliminating veining defects. Granulometric size distribution customized to avoid penetration flaws.

- High permeability spherical material, reducing or eliminating gas defects.

- Inert material, avoiding undesirable reactions with different metals & alloys, resins and additives used in the casting process.

- High strength and thermal stability to cast complex geometric and thin parts.

- Low deterioration effect in the reclaimed sand process, chemical and physical properties still as the original material producing again same high-quality casting.

- Non crystalline silica, eliminate health hazards associated with crystalline silica exposure, meeting the new OSHA silica PEL regulations.

Palmer Technical Sand Resources

Contact us at 937‑323‑6339 to learn more and confirm which product is right for you. Or email us at sales@palmermfg.com.

Brochure Palmer Technical Sand PDF

Technical Sand Casting

THERMAL EXPANSION COMPARISON

PHYSICAL AND THERMAL PROPERTIES COMPARISON

SIEVE ANALYSIS AND SHAPE

GRAIN FINENESS NUMBER INCREASE AFTER CRUSH

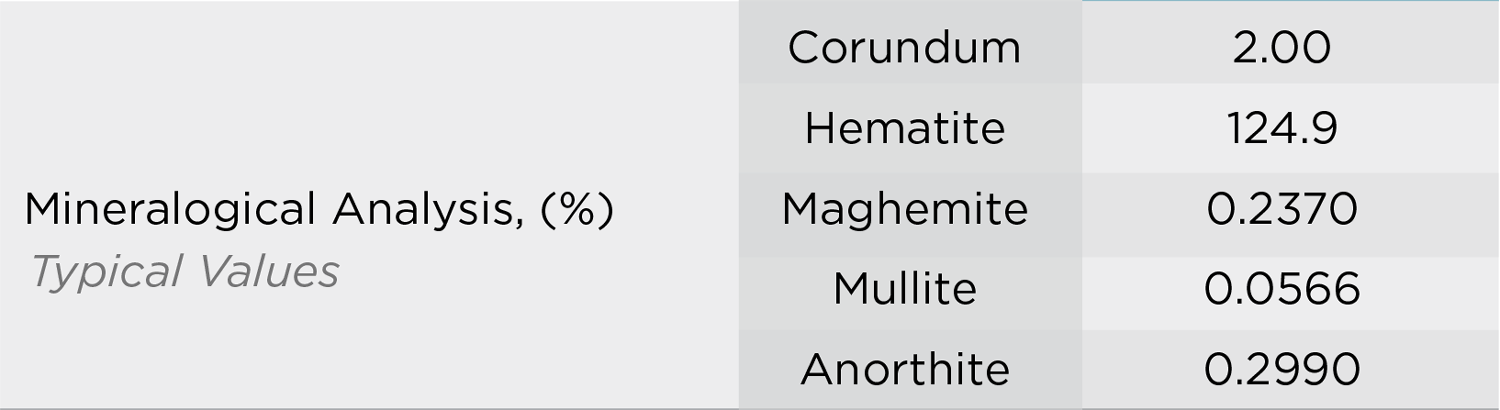

MINERALOGICAL ANALYSIS

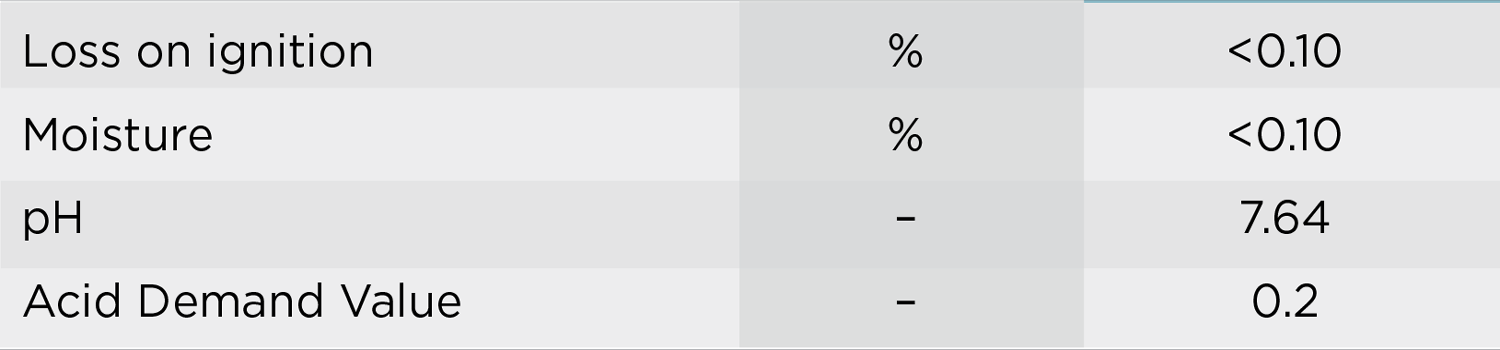

OTHER PROPERTIES

Additional Palmer Products

Improve your productivity with from Palmer.

Contact Us to learn more!

Call us at 1.800.457.5456 or fill out our simple form.

Copyright © 2025 Palmer Manufacturing & Supply, Inc. | Terms and Conditions | Privacy Policy