Foundry & industrial processing Machinery EQUIPMENT & SYSTEMS

U.S. & Canada Call 1.800.457.5456

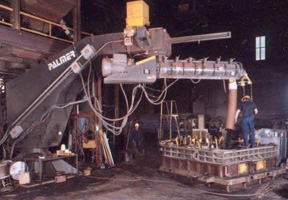

M-Series Sand Mixers Models

Home Products Sand Mixers M-Series Sand Mixers Models

M-Series high speed continuous mixer Highlights

- Foundry 4.0 Control System (whole facility approach) for decision making, process improvement, equipment utilization and real time data collection.

This integrated control system can see everything and collect the data that you want to see, in real time.- Monitor and control processes remotely

- Data collection and analysis in real time

- Production utilization

- Data for more accurate decision

- Dual doors - no tools required.

- High speed.

- Heavy duty - low maintenance.

- Easy operation.

- Tungsten carbide tipped blades.

- Precision chemical pumps.

M-Series Mixer Models

Mixer

Capacity*

(lbs/minute)

Capacity*

(tons/hour)

Rigid

Articulated

M50XLD

15-60

.45-1.8

M100XLD

50-150

1.5-4.5

M200XLD

70-250

2.1-7.5

M300XLD

150-600

4.5-18

M500XLD

300-1000

12-33

M1000XLD

400-1700

21-51

M2000XLD

1000-3000

30-90

M3000XLD

2000-5000

60-150

Palmer M-Series Mixers Standard Features

- Rugged - heavy-duty construction designed for years of use and abuse with minimal maintenance.

- Simple design -- easy to operate/maintain.

- Quick access mixing chamber dual doors. No tools required.

- Tungsten-carbide tipped mixing blades for increased life. Twice the thickness of others.

- Precision chemical pumps.

- Test run in our facility prior to shipment to ensure proper operation before it hits your dock.

- Many options available - mixer can be custom fitted to match the application's exact requirements.

- Replacement parts available from Palmer or from high quality industrial supply houses in your area. Standard off-the-shelf components are used wherever possible so that parts availability is good and affordable.

- Two year warranty.

M-Series Full Specifications

Table M-Series Comparision and Features Chart

Guide Palmer Mixer Design: In-Depth Guide

- System Overview

- Air Jets

- Control System

- Mixing Chamber/Motor Head Assembly

- Controls

- Pumping System

- Standards

Options Common M-Series Options

Mixer Kits MK-Series Mixer Kits

M-Series Resources

Article Basic Principles of Sand Mixing

Article Mixer and Compaction Calibration

Article Understanding Mixer Pumping Systems

Video Palmer M-Series XLD Continuous Sand Mixers.

Additional Palmer Products

Improve your productivity with from Palmer.

Contact Us to learn more!

Call us at 1.800.457.5456 or fill out our simple form.

Copyright © 2025 Palmer Manufacturing & Supply, Inc. | Terms and Conditions | Privacy Policy

.jpg)

.jpg)

.jpg)

.jpg)