Foundry & industrial processing Machinery EQUIPMENT & SYSTEMS

U.S. & Canada Call 1.800.457.5456

RPV Volumetric Resin Delivery System

Home Products Pumping Systems RPV Volumetric Resin Delivery System

The quality of your sand is only as good as the accuracy of your Resin Delivery System

- The RPV ELIMINATES Inaccurate, Inconsistent Resin Delivery

- The RPV ELIMINATES the Need for Constant Re-Calibration

- The RPV ELIMINATES High Parts Replacement Costs

Shipped 100% Tested, Assembled, and Ready to Install

General

The Palmer Retrofit Volumetric Resin Delivery System is a completely self contained unit to eliminate the problems associated with old, worn, poorly designed systems that cause such problems as inaccurate delivery, inconsistent delivery, resin bleed back, the need for constant re-calibration, and high replacement parts cost. The Palmer RPV is particularly helpful when used to replace resin delivery systems designed around high RPM, low displacement pumps or complicated calibration control systems.

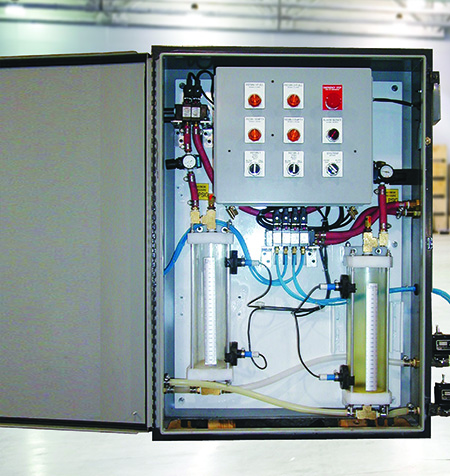

The entire RPV System is housed in a NEMA enclosure which can be mounted on or near the existing mixer. All electrical controls are housed in a smaller NEMA 12 enclosure, located within the larger enclosure for added protection. All necessary controls are accessible through a window on the door of the large enclosure.

This design allows easy access to all controls, switches, pumps, and drives, while protecting them from dust, sand, and accidental damage.

Order of Operation

- Previous cycle completes.

- Inlet ball valve opens and reservoirs are either gravity fed or pump fed via control signal

- Top liquid level proximity switch is covered

- Inlet valve closes

- Unit awaits discharge signal from mixer

- Upon signal, reservoir one empties to bottom liquid level proximity switch

- A wait timer engages prior to discharging reservoir two

- Reservoir two discharges to bottom proximity switch

- Unit refills

Electrical

The electrical control system features two modes of operation.

The first is HAND, or manual mode, in which the filling and discharge of each resin reservoir is controlled manually by the operator.

The second mode is AUTOMATIC, in which all aspects of the RPV operate based on a trigger signal from the electrical control system of the existing batch mixer.

The trigger signal is the only electrical connection required between the existing mixer and the RP.

High tolerance liquid level detection proximity switches provide for an adjustable resin amount within the resin reservoir.

System controls are managed by a state of the art smart relay system. This system offers the flexibility and power of a PLC at a fraction of the price.

Plumbing

The RPV features, as standard, two appropriately sized resin reservoirs. Each reservoir has an inlet and discharge air actuated stainless steel ball valve. The inlet valve prevents resin from bleeding back once the reservoir is filled while the discharge valve prevents seepage while filling the reservoirs.

The pneumatic system is separated into two parts. The first is the manifold which controls the air actuated ball valves. This operates off of plant compressed air.

The second manifold is used for the injection of resin into the mixer. The purpose of the separation is to allow the user to determine the transfer gas for the resins; the user can utilize either plant compressed air or inert gas for this function.

Discharge pressure of each reservoir is adjustable.

Options

- All units are sized based on batch mixer resin requirements

- Acid system upgrade

- Multiple resin levels

- Batch mixer controls integration

Pumping Systems Resources

Additional Palmer Products

Improve your productivity with from Palmer.

Contact Us to learn more!

Call us at 1.800.457.5456 or fill out our simple form.

Copyright © 2025 Palmer Manufacturing & Supply, Inc. | Terms and Conditions | Privacy Policy