Foundry & industrial processing Machinery EQUIPMENT & SYSTEMS

U.S. & Canada Call 1.800.457.5456

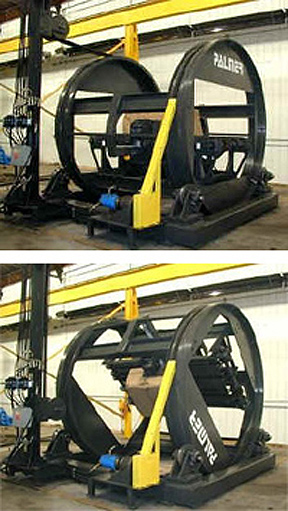

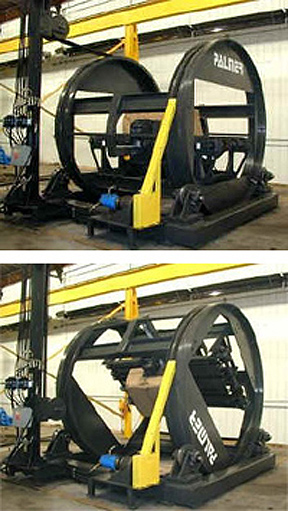

FCS-R Rotary Flow-Coating Machines

Home Products Mold and Core Coating Equipment FCS-R Rotary Flow-Coating Machines

General Description

The FCS is designed for use with all flow-coating applications. The FCS combines the rugged durability expected from Palmer equipment with the productivity dictated by today’s advanced molding systems. With automatic PLC controls available, the FCS.

Order Of Operations

- Roll mold in and center

- Initiate primary clamping

- Verify clamp pressure

- Roll to operator wash application point

- Await operator input of completion

- Roll to drip position

- Wait for drip timer

- Roll to home

- Eject mold

Custom sizes are available upon request. We can easily custom produce to meet your exact application requirements.

Features

- Heavy steel fabrication ensures years of trouble-free operation without flexure or twisting of the primary frame.

- Rotation is accomplished with a heavy-duty hydraulic motor direct mounted to a high reduction gear box for smooth, speed controlled operation. Dual speed rotation is standard.

- Large diameter, dual bearing supports ensure total support of the rotating frame.

- Four-inch diameter clamp assembly guide rollers ensure that it does not flex.

- Full hydraulic clamping provides durable motion parts requiring minimal maintenance. Clamping is accomplished with dual five-inch bore heavy-duty series hydraulic cylinders.

- Design features heavy duty “Palmerveyor” for long life, easy service, and minimal preventative maintenance.

- Dual heavy-duty clamping jaws ensure that molds are secure prior to tilting.

- High volume diaphragm pump provides maximum pump life and requires little preventative maintenance.

- Wash basin constructed of 3/16” steel reinforced for durability. Basin and construction material can be customized to fit the application’s exact needs.

Rotary Flow Coating Machines Resources

Video Palmer FCS-R Flow Coater

FCS-R Models

Standard Sizes

Nominal Mold Size

FCS-R-1000

36X48X12

FCS-R-4000

48X60X24

FCS-R-6000

60X60X24

FCS-R-10000

72X72X36

FCS-R-15000

84X84X36

Additional Palmer Products

Improve your productivity with from Palmer.

Contact Us to learn more!

Call us at 1.800.457.5456 or fill out our simple form.

Copyright © 2025 Palmer Manufacturing & Supply, Inc. | Terms and Conditions | Privacy Policy