Foundry & industrial processing Machinery EQUIPMENT & SYSTEMS

U.S. & Canada Call 1.800.457.5456

Pouring Cup Molds, Rigging Components, Mold Anti-Shifts

Home Products Foundry Products/Misc Pouring Cup Molds, Rigging Components, Mold Anti-Shifts

"Super-Slick Plastic" Rigging, Gating, and Test Bar Components

Overview

Using this new, more wear resistant, and slick surface plastic allows us to build light-weight single and multi cavity dump boxes. This new plastic has excellent machinability. It can be molded onto metals in addition to being the most perfect material for Pattern and Corebox construction. All plastic boxes made out of this new material will produce many hundreds of thousands of no-bake sand basins without any repair or breakdown. They are nearly impossible to wear out!

General Characteristics:

- Super - Slick – Plastic is not a two part Type A and Type B material.

- Super - Slick – Plastic recommended not to be used above 200 degrees.

- Super - Slick – Plastic comes in orange color - on special request in black.

- Super - Slick – Plastic standard sheets hardness is D-75 Durometer.

- Super - Slick – Plastic special sheets can be cast from A-60 to D-75 Durometer.

- Super - Slick – Plastic weight of 12" x 12" x 1" = 6.3 lbs.

- Super - Slick – Plastic weight of 12" x 12" x 12" = 75.6 lbs.

- Super - Slick – Plastic is the plastic of the future now!

Specific Advantages:

This plastic is the best on the market today for many reasons:

- Its high adaptability;

- Its super high wear resistance;

- Its superior ease of mold releasing;

- It can be poured into almost any shape;

- It can be molded onto any metal.

Availability

- We are building tooling for this plastic to produce light weight single or multi-cavity patterns, core boxes, or any other parts where the quality of this plastic is needed.

- Super - Slick - Plastic comes in sheets of 31.5" x 55" x 1/4" and thicker = 12 sq. ft. as well as in blocks of various sizes and in round stock or tubing.

- Once you have experienced our Super - Slick - Plastic you will find many other uses for this remarkable material.

Resources

Mold Anti-Shifts

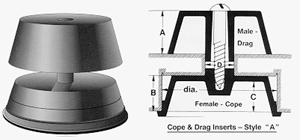

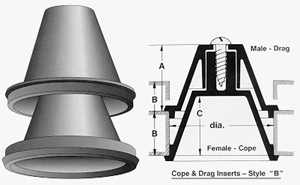

Our patented Cope & Drag Inserts create a quick, simple and accurate alignment of cope & drag mold halves. They eliminate the need for line up cores, are easily installed and guarantee a perfect match. Use them on matchplates, matchboards, insert or cope & drag boards, in molding boxes for flaskless molding, on automatic molding machines for core alignment, etc. . . . Once you have used them and have experienced the efficiency and time savings they provide, you will use them for all your mounted patterns. Two or three inserts are all it takes to correct any wear on pins or misalignment problems you may have. They work independent from alignment pins, are mounted next to patterns, and create holes and corresponding buttons in each mold half. They are used in greensand, airset / no-bake molding, in vacuum molding for sandcastings, on automatic molding machines, and many other ways. We have two different styles of inserts: style "A" and style "B". Both have mounting rims, which guarantee the correct depth of the female insert. These rims and the additional height of the male insert leave impressions in the sand, which become sand traps, necessary for flaskless molding. They also make it possible to use either insert half on the cope or drag side.

Style "A" Inserts consist of two parts: one male and one female. They are used in two ways: mounted on matchboards one above the other, or separated like on cope & drag boards or molding boxes. They are available in 4 sizes and 3 different depths, and are made out of ABS plastic.

Style "B" Inserts consist of two parts, specially designed for matchplates and matchboards including automatic molding machines. Both halves telescope together, and interlock at the parting line in a hole through plates or boards of various thickness. Their interlocking creates the deepest matching buttons possible. On 3/8" or 1/2" thick plates they produce 3/4" or 1" deep buttons. They can be mounted from either side, and one screw will keep both halves securely mounted. Stvle "B" Inserts are made out of a tough new, non-sticking and acid-resisting plastic, and are available in 3 sizes and 2 different depths.

To be able to install our inserts easily into wood, we have designed a cutter holder with a long I/2" diameter pilot and interchangeable cutting blades for all sizes of our inserts.

Also available is a short Video tape explaining the advantages of our inserts, showing how to install them, and when to use style "A" or style "B" inserts.

As tested by a pattern maker with over forty years experience, we have designed, tested and retested our inserts, and guarantee them to be the fastest and easiest way of creating perfect alignment of mold halves for the best quality castings possible.

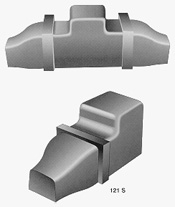

Gating Components

Our Patented nbsp;Pouriniz-Filteriniz-Riser-Basins are specifically designed to assist foundries in pouring and filtering their metals. These no-bake basins are used in greensand and flaskless molding, and they are strong enough for pouring steel. Each basin is designed for a specific filter, and combines pouring, filtering and even risering into one step. Since air-set molding has opened the door for a better and easier way of making castings, our pouring basins will help you even more to cut cost. During our testing for better products we developed a remarkable new plastic - the "SUPER-SLICK-PLASTIC." Nothing sticks to this new material, and it outlasts steel in wear resistance many times.

Pouring Cup Core Box

With the increased usage of molten metal filters, a need has arisen for a simple, productive means to produce standard pouring cups for these filters. This item is ideal for green sand and no-bake molding floors where there is insufficient time to custom produce pouring cups or the like and where insulating sleeves used for filtering are too expensive.

Additional Palmer Products

Improve your productivity with from Palmer.

Contact Us to learn more!

Call us at 1.800.457.5456 or fill out our simple form.

Copyright © 2025 Palmer Manufacturing & Supply, Inc. | Terms and Conditions | Privacy Policy