Foundry & industrial processing Machinery EQUIPMENT & SYSTEMS

U.S. & Canada Call 1.800.457.5456

Pumping System Options

Home Products Pumping Systems Pumping System Options

Control System Options

3rd Part Pump

This option provides a DC voltage precision metering pump for three part phenolic urethane applications.

Hastalloy Pump

This provides a wetted packing sealed gear pump made of Hastalloy-C steel for acid catalyst applications. This option includes a PVC air actuated ball valve.

Ryton Pump

This provides a wetted packing sealed gear pump made of fiberglass reinforced Ryton composite pump body and gears for acid catalyst applications. This option includes a PVC air-actuated ball valve.

Stainless Steel Pump

This provides a wetted packing sealed gear pump made of stainless steel for some acid catalyst applications. This option includes a stainless steel air actuated ball valve. This is a lower cost option than the Hastalloy-C pump option but will not be as compatible with most acids.

Isoset Pumping System

This upgrade consists of all required components for use with the Isoset or comparable resin system. It includes a stainless steel pump one and ball valve as well as a continuous cavity, non-shearing pump 2 and pneumatic pinch valve set. Note that this system is set up for recirculation of liquid components.

2nd Coreactant Pump

This option works well for production floors that require two different mold set-up rates with a binder system that requires different activators for different set-up speeds. This option is commonly used with ester-cured phenolics, sodium silicates, and other binder systems where the amount of activator does not affect strip time as much as the chemical composition.

2nd Acid Pump

This option works well for production floors that require two different mold set-up rates with a furan or other acid based binder system that require different activators for different set-up speeds. This option can be used with Ryton, Stainless Steel, or Hastalloy-C pumps.

Recirculating Pumps

The option replaces the two-way air actuated ball valves provided with the standard pumping system with three way valves. The resin pumps run continuously and the three way ball valves divert to the mixing chamber when called on. This system is helpful in maintaining resin temperature and when utilizing flow meters for liquid usage measurement and control.

Magnetically Coupled Pumps

This option replaces the standard system pumps with magnetically coupled, micro gear pumps. The pumps are DC driven, identical to the standard pump, but they operate in a recirculating manner. The magnetic coupling provides seal-less operation, which eliminates any maintenance associated with pump shaft seal replacement. Also included with this option are recirculating diverter valves for each pump.

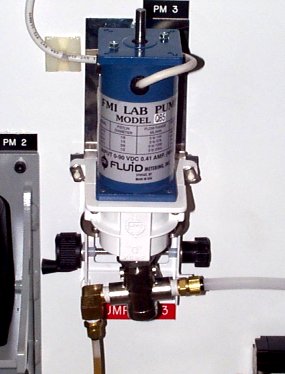

Trial Pumping System

This option is ideal for foundries that regularly perform trials or switch binder systems. The standard pumping system pictured is easily interchangeable and upgradeable. For a full description of the controls and capabilities, refer to the Retrofit Pumping System section of this web-site.

Additional Palmer Products

Improve your productivity with from Palmer.

Contact Us to learn more!

Call us at 1.800.457.5456 or fill out our simple form.

Copyright © 2025 Palmer Manufacturing & Supply, Inc. | Terms and Conditions | Privacy Policy