Foundry & industrial processing Machinery EQUIPMENT & SYSTEMS

U.S. & Canada Call 1.800.457.5456

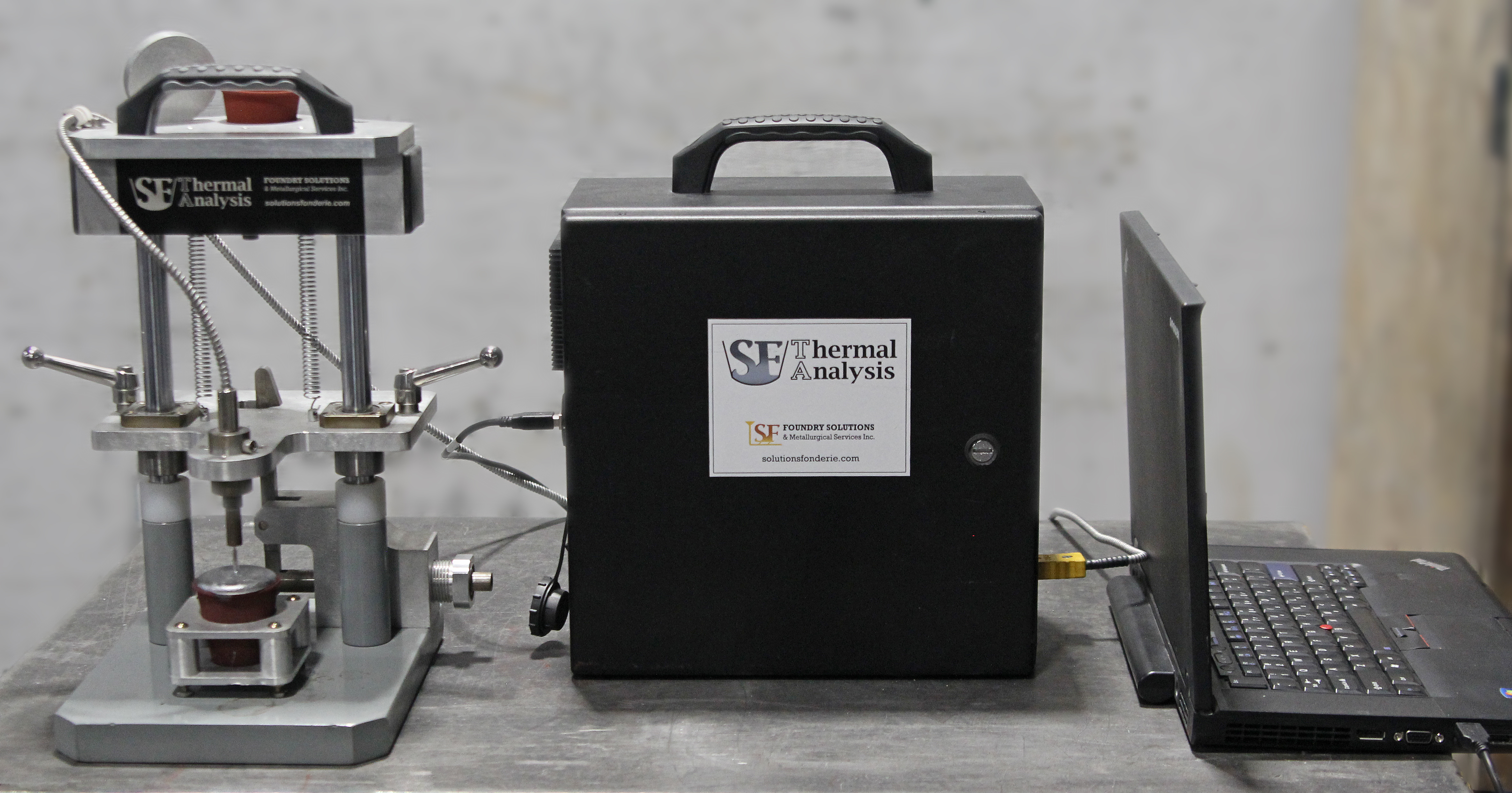

Foundry Solutions Thermal Analysis System

Better Melt Control Reduces Defects

Overview

The Foundry Solutions Thermal Analysis System (SFTA) provides a complete thermal analysis solution for measuring solidification properties, including grain refinement and eutectic modification, in aluminum alloys directly on the shop floor—in just 2 to 6 minutes! This affordable and comprehensive system enables rapid adjustments to melt treatment, reduces defects, and ensures consistently high-quality casting production.

Foundry Solutions Thermal Analysis System Resources

Brochure STFA brochure (PDF)

Article SFTA Article (PDF)

Video

Advantages

- Accurate measurement for eutectic modification & grain refinement

- Evaluate the intermetallics Mg2Si, Al2Cu

- Detect casting defects, reducing scrap

- Calibrate easily by your operators

- Measure true solid fraction curve for better simulation and modeling

- Validate and control raw materials

Grain Refinement

Use the SFTA system to manage grain refinement to reduce defects caused by porosities and shrinkage.

- Verify grain refinement level before casting

- Optimize grain refiner usage for desired results

- Determine appropriate treatment intervals

- Reduce hot tearing

Eutectic Modification

Use the SFTA system to manage eutectic modification, ensuring consistent casting quality.

- Target lower strontium to minimize the drawback

- Control the modification treatment

- Adjust the melt process

- Ensure consistent mechanical properties

Improve your productivity with from Palmer.

Contact Us to learn more!

Call us at 1.800.457.5456 or fill out our simple form.

Copyright © 2025 Palmer Manufacturing & Supply, Inc. | Terms and Conditions | Privacy Policy